- Home

- About

- International Office

- Academics

- Research and Transfer

HSBI and the University of Tübingen Are Developing an Alternative to Glyphosate

Glyphosate reliably destroys unwanted plants, is used worldwide – and has been hotly disputed for years because of its negative effects on the environment and health. A ban on the herbicide in Germany and possibly even in the whole EU has hung in the air for a long time. Good thing that a better alternative is in sight: in a cooperation project with the University of Tübingen funded by the Federal Ministry for Education and Research, doctoral candidates at HSBI are working on an environmentally friendly herbicide based on a natural sugar from cyanobacteria. The preliminary results are promising.

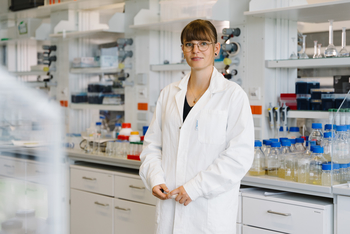

Bielefeld (hsbi). Neatly labelled, the centrifuge tubes are lined up in their holders in the Laboratory for Biochemistry and Microbiology at Hochschule Bielefeld – University of Applied Sciences and Arts (HSBI). Celina Beermann is putting on her white lab coat. She takes out one of the tubes, gives it a few well-versed shakes and checks it by holding it against the light: small transparent capsules are swirling through a fluid. Beermann makes a few of them roll on her palm. “They feel a bit like gummy bears.”

The special sugar was not discovered until 2019 at the University of Tübingen

Although Celina Beermann is a food chemist, you had better not try her “gummy bears:” they contain 7-deoxy-sedoheptulose (7dSh) – a special sugar produced by cyanobacteria. “7dSh has a herbicidal effect, which means it inhibits the growth of plants,” Beermann explains. That may not sound spectacular, but it actually means that 7dSh is a real alternative to glyphosate, the globally used weed killer that may be banned due to its negative impact on the environment and health. And above all, 7dSh is an environmentally friendly alternative. “The sugar is of biological origin, it’s biodegradable and so far, it has not shown any toxicity in tests,” says Beermann. This makes it an ideal, sustainable active substance for use in agriculture.

How the active substance 7dSh can become an applicable product is currently being researched in a cooperation project between HSBI and the University of Tübingen where the special sugar was first discovered in 2019. Within the project, one of HSBI’s tasks is to develop a so-called formulation. In this context, formulation simply means the transfer of an active substance into a form that can be used in practice.

Can the cyanobacterial sugar keep Deutsche Bahn’s track beds weed-free?

7dSh – a cyanobacterial natural sugar on the way to sustainable herbicide formulation

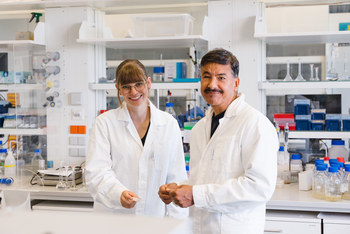

Deutsche Bahn is not entirely innocent of the cooperation: “Deutsche Bahn had organised a workshop to discuss alternatives to using glyphosate in the track beds,” says Prof. Dr. Anant Patel, Vice President for Research and Development at HSBI, who has been researching and publishing on natural pesticides for many years. As an expert in the fermentation and formulation of biologicals and chemicals, Patel was a participant in the workshop and pricked up his ears when researchers from Tübingen presented the active substance 7dSh produced by cyanobacteria. Patel: “The effect and the environmental properties convinced me at once.”

But how does the active substance get to where it is needed – on the plant or into the soil – in sufficient quantities? Here, Patel was able to contribute his expertise: “An appropriate formulation, e.g. as granules or a spray solution, facilitates the application,” Patel explains and with a wink he adds: “Some might say that it is only the formulation that makes application possible at all.” It quickly became clear that the competences in Tübingen and Bielefeld complemented each other excellently for the development of 7dSh into a marketable and competitive product. A joint project was a done deal and the Federal Ministry of Education and Research gave both its blessing and the necessary funding. “The project fills the gap between fundamental research and application,” says Patel, putting the research contribution into context.

Samples are sent back and forth between Bielefeld and Tübingen

At the University of Tübingen, the exact mode of action of 7dSh is now being clarified, the ecotoxicological effects compared to glyphosate are being measured and 7dSh-tolerant varieties are being developed. “After all, we intend the crops to keep growing,” says Celina Beermann. She herself is a doctoral candidate in Professor Patel’s working group and conducts research on the optimum formulation, which includes finding a suitable carrier material. Beermann has tested various materials for the granules: “Of course, it is important that they, too, are of biological origin and easily degradable.” The transparent capsules, for example, consist of renewable raw materials. Then the content must be considered: “How much sugar can I put into such a capsule and how quickly does it dissolve? The active substance is best dispensed continuously over a long period of time, as farmers are not able to apply the product on a daily basis,” Beermann explains.

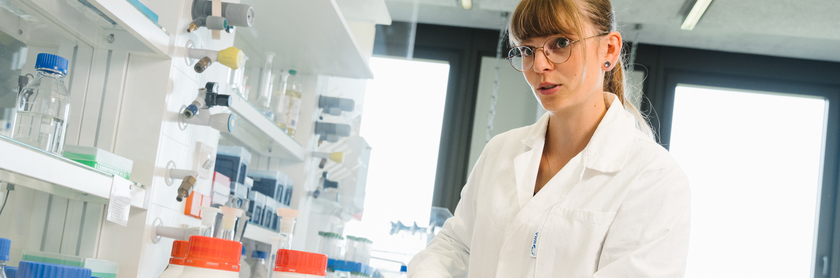

The 27-year-old researcher opens a tall device: thin tubes become visible, a carrier full of injection vials, a measuring device. This device – called HPLC, which stands for High-Performance Liquid Chromatography – can measure the concentration of the active substance in the liquid. If Beermann is satisfied with the result, she sends the corresponding samples to Tübingen. “The researchers there subsequently try the formulation on the plants. Because what works well in the laboratory can behave quite differently in practice.”

How can large-scale production of the environmentally friendly herbicide be realised?

This also applies to the scale. While the amount of sugar for laboratory requirements can be financed easily, large-scale application would still be too expensive. This is where Xenia Steurer’s sub-project in Bielefeld comes in. The biotechnologist practically assumes the cyanobacteria’s role and produces 7dSh in the bioreactor: “It must be possible to produce the active substance economically and in large quantities if it is to be used in practice.” The prospect of later application is exactly what drives the doctoral candidate: “It is important to me that my research can contribute to environmental protection and that the active substance may be sold by a company as a sustainable herbicide one day.” Beermann agrees: “What’s particularly fascinating about our research is its orientation towards application.”

And they are on the right track. Constant exchange within the project group and close links between the various sub-projects have led to promising interim results. Xenia Steurer has already been able to increase production volumes beyond expectations and Celina Beermann’s formulations help control the active substance’s effect better and better. Among experts, the research conducted in Bielefeld and Tübingen has sparked interest, too: Xenia Steurer recently received an award for her presentation at an international environmental symposium on biotechnology and engineering. Both doctoral candidates have already taken the opportunity to present their results at international conferences, for example, at the conferences of the Gesellschaft für Chemische Technik und Biotechnologie DECHEMA in Aachen, Berlin and Granada, at Deutsche Pflanzenschutztagung in Göttingen and at Deutsche Lebensmitteltechnikertage in Hamburg. The next step leads to the industry. Anant Patel: “Companies are immensely interested and plans for cooperation after successful project completion are already being made.” (uh)

For more photographic material, please contact presse@hsbi.de.